Scientific Network

Funding and Industrial Partners

Our Team

Head of the CD-lab

Univ.-Prof. Dipl.-Ing. Dr.mont. Susanne Michelic

Scientific Employees

Shashank Ramesh Babu

Post-Doc

Inclusion Analytics

Kathrin Thiele

PhD candidate

Tracing of Inclusions

Julian Cejka

PhD candidate

SecMet for Alternative Steelmaking Routes

Manuel Schickbichler

PhD candidate

Powder Metallurgy

Nikolaus Preisser

PhD candidate

Alkali-Oxide in Secondary Metallurgy

Robert Musi

PhD candidate

AI assisted Steel Cleanness Optimization

Bernhard Sammer

PhD candidate

Electrical Steel

Student workers

Isabell Gruber

Master Student

Inclusion and Material Properties

Jakob Rinnofner

Bachelor Student

Lab Experiments and Metallography

Stefan Breyer

Bachelor Student

Lab Experiments and Metallography

Nathalie Hansal

Bachelor Student

Lab Experiments and Metallography

Non-Scientific Employees

Jannik Wiesel

Technician

Lab Experiments and Metallography

Christine Lackner

Administration-Controlling

Ziad Babilli

IT- and Data-management

Our Research

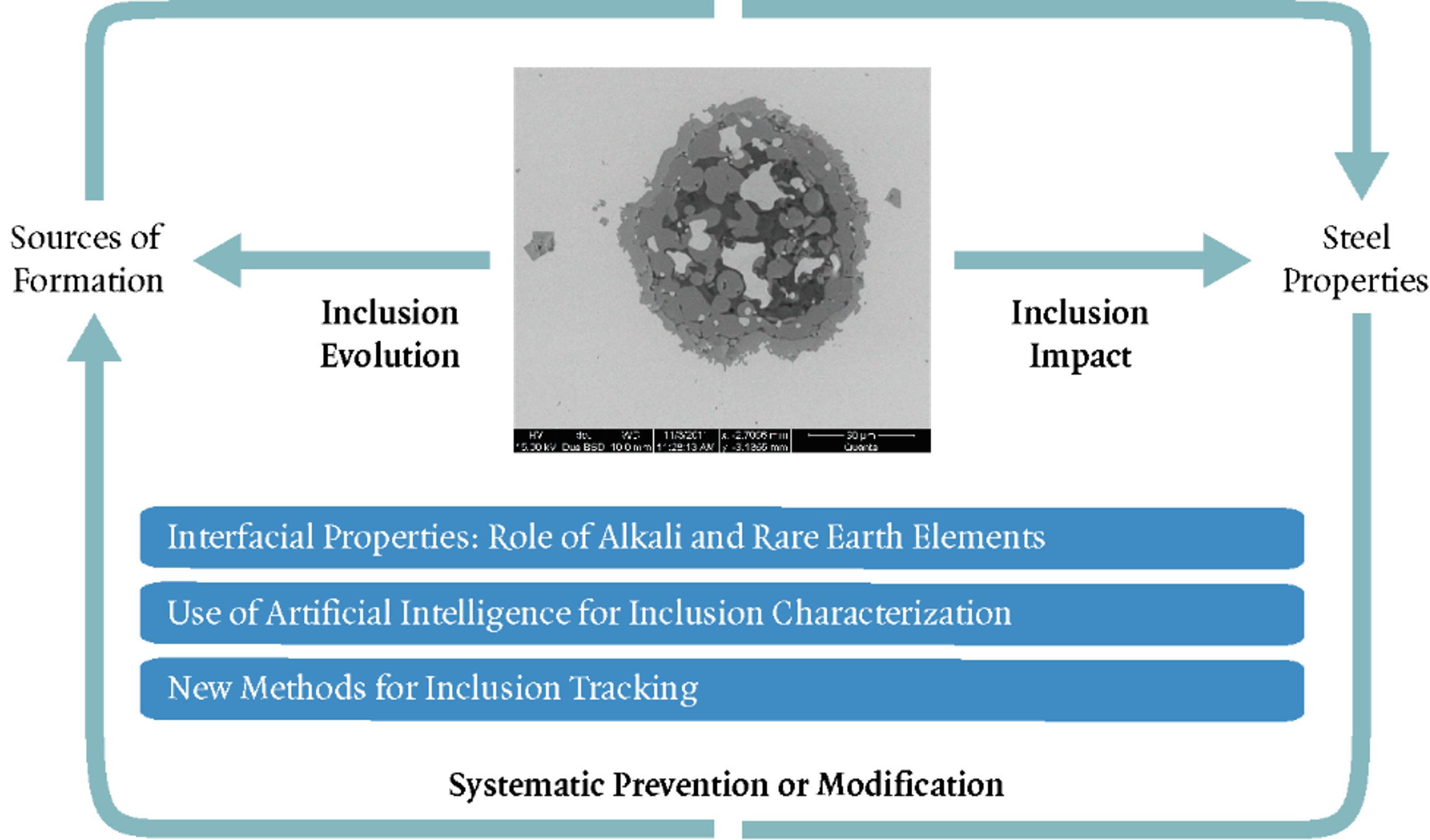

Current challenges related to climate change and digitalization lead to new trends in steelmaking and imply new questions for steel producers and their customers. With changing input materials and process steps, controlling and optimizing inclusion metallurgy is essential to ensure satisfactory product quality. The Christian Doppler Laboratory focuses on research concerning the presence of non-metallic inclusions in different steelmaking processes, their formation, modification, and their impact on final material properties.

« Steel is a “composite” material nonmetallic inclusions being inevitably present. »

Holappa and Helle,1995.

The Research Field

Requirements on steel products increase continuously due to the rising demands in their application as well as the evolving competition of other materials. Although steel production has a very long history and product development has always been accompanied by continuous improvement and innovation in steel processing, steelmakers are still facing challenges today to further improve both.

Steelmaking and casting inevitably involve the presence of so-called non-metallic inclusions in the steel as one of these challenges. Non-metallic inclusions (NMI) are particles with a different nature compared to the surrounding matrix (steel). Most of them are generally seen to affect product quality through initiating various material failures negatively. The term Steel Cleanness is principally used to describe the number, size, chemical composition, morphology and distribution of non-metallic inclusions in the steel matrix. The demands to steel cleanness are inevitably connected to the individual application of the steel and material requirements since the properties of the steel are directly linked to its cleanness.

The research field Inclusion Metallurgy covers various aspects regarding the formation, evolution, removal as well as the characterization of non-metallic inclusions at different stages of steel production. Additionally, non-metallic inclusions also have the potential to act as nucleation sites for specific microstructure evolution, thus enhancing mechanical properties. To further optimize the already very high purity level in cleanness-sensitive steels as well as the upcoming questions for secondary metallurgy due to alternative ways for crude steel production, are main challenges today.

The Research Approach

The aim of the CD laboratory is to intensify and further deepen research in the field of Inclusion Metallurgy especially focusing on open questions from a scientific point of view as well as application-oriented subjects in cooperation with the industry partners. The principal idea is to establish a bridge from inclusion formation over their modification and evolution in the system steel-slag-refractory to their final impact on material properties for specific applications. With this approach, the primary aim is to study the relation and interaction between micro-, meso- and macro-cleanness in steel with a special focus on meso-cleanness.

Different process routes and completely various products will be investigated regarding steel cleanness related issues: From integrated steel mill with classical secondary metallurgical processes to powder metallurgical production with Electroslag Heating followed by atomization; from steels for automotive applications to cold work tool steels for precision blanking. However, basic mechanisms and scientific questions related to Inclusions Metallurgy are comparable.

Especially the further development of inclusion analytics, also considering machine learning tools to support inclusion characterization and the representative analysis of meso-particles, as well as different aspects regarding interfacial properties influencing the inclusion behavior, are in the focus of interest. Special attention will be paid on the role of different alkali and rare earth elements changing the inclusions behavior in the system steel-slag-refractory to their final impact on material properties for specific applications.

Objectives:

1. Specific creation of defined inclusion populations on laboratory scale especially considering the role of alkali and rare earth elements; Investigation of the inclusion behavior in the system steel-slag-refractory by means of different experimental methods.

2. Development of a deepened understanding regarding inclusion morphology through the combination of various methods for inclusion analytics focusing on multiphase particles.

3. Linking different analytical tools considering data-driven modeling by means of machine learning for a more efficient inclusion characterization.

4. Systematic, multi-scale analysis and tracking of non-metallic inclusions, especially for the meso-size range.

5. Establishment of isotope analysis for inclusion tracking in the system steel-slag-refractory.

Our Projects

With the CD laboratory, three projects are conducted in cooperation with one industry partner each:

Research Project I: NMI-PM

Industrial Partner: voestalpine Böhler Edelstahl GmbH & Co KG

This project focuses on the behavior of non-metallic inclusions in the powder metallurgical production of tool and high speed steels and the therewith connected potential for further optimization of the already very high steel cleanness level. Based on a deepened understanding of the relation between specific aspects of steel cleanness and the fatigue behavior under defined stresses and loads, the need for excessive material testing should be reduced.

Research Project II: SECMET-SURACT

Industrial Partner: voestalpine Stahl Donawitz GmbH

The main focus of this project is on the challenges of secondary metallurgy in the context of alternative routes for crude steel production based on the Direct Reduction/Electric Arc Furnace process. This includes an examination of the role of treatments with various (tracer) elements, such as alkali or lanthanide groups, to improve inclusion removal.

Research Project III: MESO-INC

Industrial Partner: voestalpine Stahl GmbH

The aim of this project is to study the behavior of inclusions in different steel grades for automotive applications, especially considering the role and impact of meso-inclusions. For this purpose, a multi-scale inclusion characterization, as well as a systematic tracing of particles over the production process by different methods, are of significant interest and importance. This part of the project includes a scientific cooperation with the Chair of General and Analytical Chemistry at Montanuniversitaet Leoben.

In the context of ongoing electrification, a further key aspect of this project is gaining an understanding of non-metallic inclusions and their influence on material properties, including magnetic losses, in electrical steel.

Furthermore, this project deals with the application of artificial intelligence to tackle digitalization challenges and improve the efficiency of quality control systems regarding steel cleanness.

Publications

S. Ramesh Babu and S.K. Michelic, Overview of application of automated SEM/EDS measurements for inclusion characterization in steelmaking. MetalMat (2024). doi:10.1002/metm.18

S.K. Michelic and C. Bernhard, Significance of Nonmetallic Inclusions for the Clogging Phenomenon in Continuous Casting of Steel––A Review. steel research int. 93 (2022), 7. doi:10.1002/srin.202200086

W. Mu, S.K. Michelic and Q. Wang, Editorial: Inclusion/Precipitate Engineering and Thermo-Physical Properties in Liquid Steels and Alloys. Front. Mater. 9 (2022). doi:10.3389/fmats.2022.922203

S. Ramesh Babu and S.K. Michelic, Overview of application of automated SEM/EDS measurements for inclusion characterization in steelmaking. MetalMat (2024). doi:10.1002/metm.18

S. Ramesh Babu, R. Musi and S.K. Michelic, Comparison between image based and tabular data-based inclusion class categorization. Practical Metallography 60 (2023), 10, pp. 660-675. doi:10.1515/pm-2023-0056

S. Ramesh Babu, N. Preisser and S.K. Michelic, Image Processing Procedure to Evaluate Inclusion Dissolution in a Slag Observed by High-Temperature Confocal Scanning Laser Microscopy. Metals 12 (2022), 4, pp 531. doi:10.3390/met12040531

S. Ramesh Babu and S.K. Michelic, Analysis of Non-Metallic Inclusions by Means of Chemical and Electrolytical Extraction—A Review. Materials (Basel Switzerland) 15 (2022), 9. doi:10.3390/ma15093367

S. Ramesh Babu, R. Musi, K. Thiele and S.K. Michelic, Classification of non-metallic inclusions in steel by data-driven machine learning methods. steel research int. 94 (2022), 1. doi:10.1002/srin.202200617

Conferences:

S. Ramesh Babu, R. Musi and S.K. Michelic, Comparison between image based and tabular data-based inclusion class categorization. Metallografietagung, Leoben (2023)

K. Thiele, C. Truschner, C. Walkner, T.C. Meisel, S. Ilie, R. Rössler and S.K. Michelic, Investigating the Origin of Non-Metallic Inclusions in Ti-Stabilized ULC Steels Using Different Tracing Techniques. Metals 14 (2024), 1, pp. 103.

doi:10.3390/met14010103

C. Truschner, K. Thiele, S. Ilie, R. Rössler, A. Jungreithmeier and S.K. Michelic, Tracing of Deoxidation Products in Ti-Stabilized Interstitial Free Steels by La and Ce on an Industrial and Laboratory Scale. steel research int. (2023), doi:10.1002/srin.202300665

K. Thiele, R. Musi, T. Prohaska, J. Irrgeher and S.K. Michelic, AI assisted steel cleanness evaluation: Predicting the morphology of La-traced non-metallic inclusions using backscattered-electron images. Journal of Materials Research and Technology 28 (2023), pp. 2247-2257. doi:10.1016/j.jmrt.2023.12.172

K. Thiele, S. Ilie, R. Roessler, C. Walkner, T.C. Meisel, T. Prohaska and S.K. Michelic, Different Approaches to Trace the Source of Non-metallic Inclusions in Steel. Iron & Steel Technology 20 (2023), 7. doi:10.33313/TR/0723

K. Thiele, R. Musi, S. Ramesh Babu and S.K. Michelic, Optimization of the Two‐ and Three‐Dimensional Characterization of Rare Earth‐Traced Deoxidation Products. Adv Eng Mater 25 (2023), 11. pp. 2201748. doi:10.1002/adem.202201748

K. Thiele, P. Presoly, D. Ernst, S. Ramesh Babu and S. K. Michelic, Evaluation of different alloying concepts to trace non-metallic inclusions by adding rare earths on a laboratory scale. Ironmaking & Steelmaking 50 (2022), 5, pp. 507-516. doi:10.1080/03019233.2022.2124816

Conferences:

K. Thiele, C. Truschner, C. Walkner, Thomas C. Meisel, S. Ilie, R. Rössler and S.K. Michelic, Application of tracing techniques to determine the source of alumina inclusions in the clogging layer of Ti-stabilized ULC steels. International Conference on Secondary Refining and Inclusion Controlling SRIC 2023, China (2023)

K. Thiele, C. Truschner, C. Walkner, S. Ilie, R. Rössler and S. K. Michelic, Comparison of tracing deoxidation products with rare earth elements in the industry and on a laboratory scale. 6th European Steel Technology and Application Days, Düsseldorf, Germany (2023)

K. Thiele, S. Wagner, C. Walkner, T.C. Meisel, J. Irrgeher, T. Prohaska and S.K. Michelic, Tracing the origin of non-metallic inclusions by elemental and isotopic fingerprints, Junganalytiker*innen Forum, Montanuniversitaet Leoben,

Austria (2023)

K. Thiele, S. Ilie, R. Roessler, C. Walkner, T.C. Meisel, T. Prohaska and S.K. Michelic, Different Approaches to Trace the Source of Non-Metallic Inclusions in Steel. AISTech 2023, Huntington Place, Detroit, Michigan, USA

K. Thiele, S. Ilie, R. Roessler, C. Walkner, T.C. Meisel, T. Prohaska and S.K. Michelic (Speaker), Different Approaches to Trace the Source of Non-Metallic Inclusions in Steel. 8th International Congress on the Science and Technology

of Steelmaking (ICS), Montreal, Kanada (2022)

K. Thiele, S. Ilie, R. Rössler and S.K. Michelic, Characterization of Rare-Earth-Elements-Traced Non-Metallic Inclusions by Different Methods, 8th International Congress on the Science and Technology of Steelmaking (ICS), Montreal, Kanada (2022)

K. Thiele, C. Walkner, T.C. Meisel, T. Prohaska and S.K. Michelic, Application of ICP-MS to study the evolution of non-metallic inclusions in steelmaking, 28. ICP-MS ANWENDER*INNEN TREFFEN, Montanuniversität Leoben, Österreich (2022)

K. Thiele, S. Ilie, R. Roessler, A. Penz and S.K. Michelic, Tracing of Non-metallic Inclusions in Secondary Metallurgy by Means of Rare Earth Elements. ASIA STEEL 2021 jointed with Automotive Steel International Conference, Gyeongju, Korea (2021)

J. Cejka and S. K. Michelic, In-Situ Observation of Steel/Slag/Inclusion Interaction by Means of High-Temperature Confocal Scanning Laser Microscopy. Metals 13 (2023), 4, pp 686. doi:10.3390/met13040686

M. Häuselmann, J. Rieger, J. Schenk, R. Schnitzer, A. Sakic, S.K. Michelic and J. Cejka, How to increase scrap recycling. Steel times int. (2022)

Conferences:

J. Cejka, G. Klösch and S.K. Michelic, The impact of tramp elements on the wetting behavior of non-metallic inclusions in a medium-carbon steel. International Conference on Secondary Refining and Inclusion Controlling SRIC 2023, China (2023)

J. Cejka, B. Sammer, N. Preißer, G. Klösch and S.K. Michelic, Consequences of an increased content of tramp elements in steel on the wetting conditions in the system steel-inclusion-refractory. 6th European Steel Technology and Application Days, Düsseldorf, Germany (2023)

J. Cejka, G. Klösch, P. Presoly and S.K. Michelic, Influence of specific trace elements on the wetting behaviour of a medium-carbon steel in contact with different oxidic substrates. Material Sciene and Engineering MSE Darmstadt, Germany (2022)

M. Schickbichler, S. Ramesh Babu, M. Hafok, C. Turk, G. Schneeberger, A. Fölzer and S.K. Michelic, Comparison of methods for characterising the steel cleanness in powder metallurgical high-speed steels, Powder Metallurgy 66 (2023), 4, pp. 316-332. doi:10.1080/00325899.2023.2170848

Conferences:

M. Schickbichler, M. Hafok, C. Turk, G. Schneeberger, A. Fölzer and S.K. Michelic, Description of Inclusion Population in a High-Speed Steel produced via Powder Metallurgy. 6th European Steel Technology and Application Days, Düsseldorf, Germany (2023)

M. Schickbichler, K.Thiele and S.K. Michelic, Evaluierung der Unterschiede zwischen sequenzieller chemischer und elektrolytischer Extraktion anhand von Seltene Erden (SE)-haltigen Einschlüssen. Metallografietagung, Leoben (2023)

Conferences:

N. Preisser, J. Cejka, K. Thiele, G. Klösch, and S.K. Michelic, Investigation of inclusion evolution in a medium carbon steel through contact with secondary metallurgical slags containing alkali oxides. 6th European Steel Technology and Application Days, Düsseldorf, Germany (2023)

N. Preisser, J. Cejka (Speaker), S. Ramesh Babu, G. Klösch and S.K. Michelic, Dissolution of Al2O3, MgO.Al2O3, and SiO2 in alkali oxide containing secondary metallurgical slags. Liquid Metal Processing & Casting Conference (LMPC), Philadelphia, USA (2022)